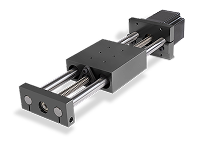

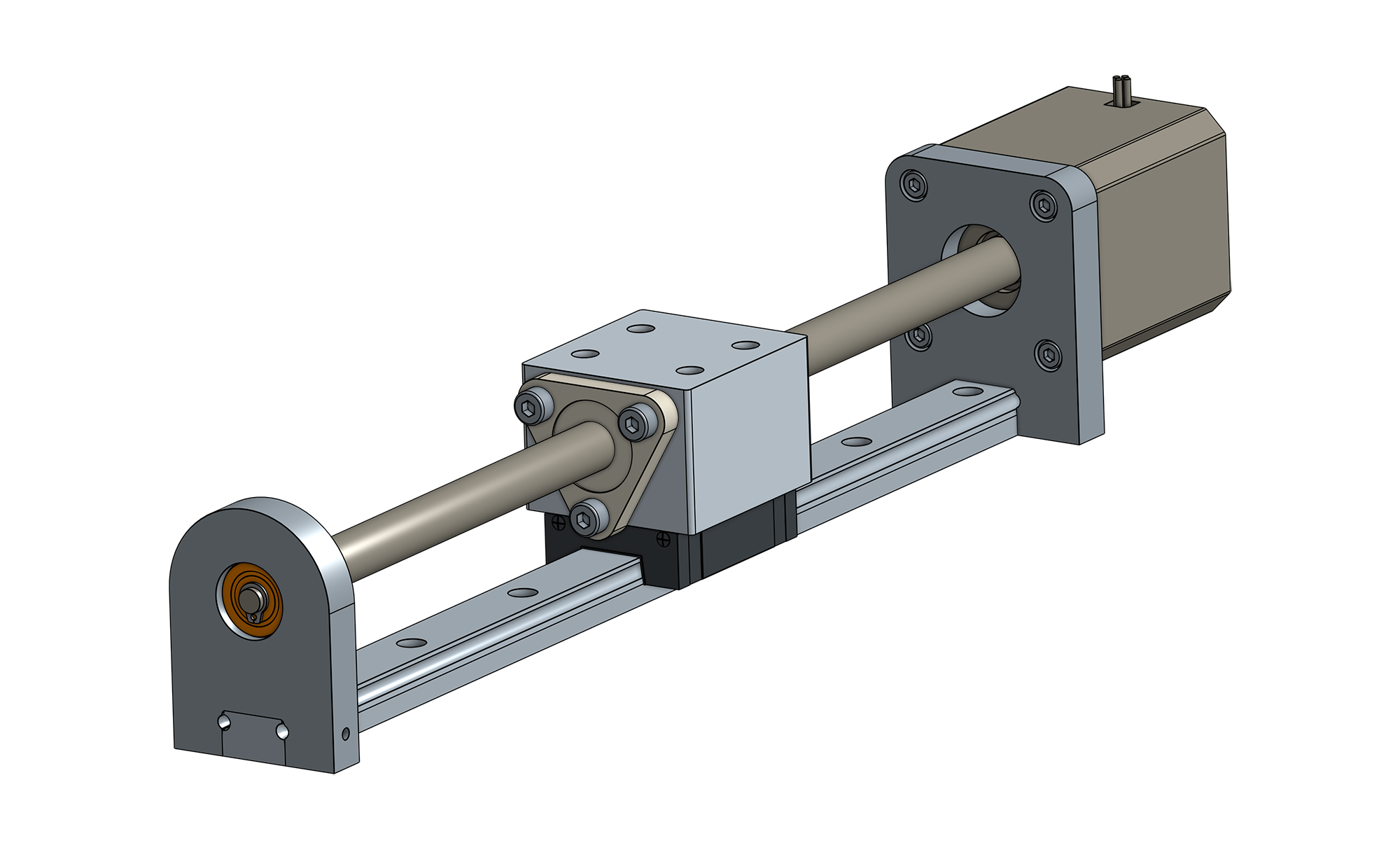

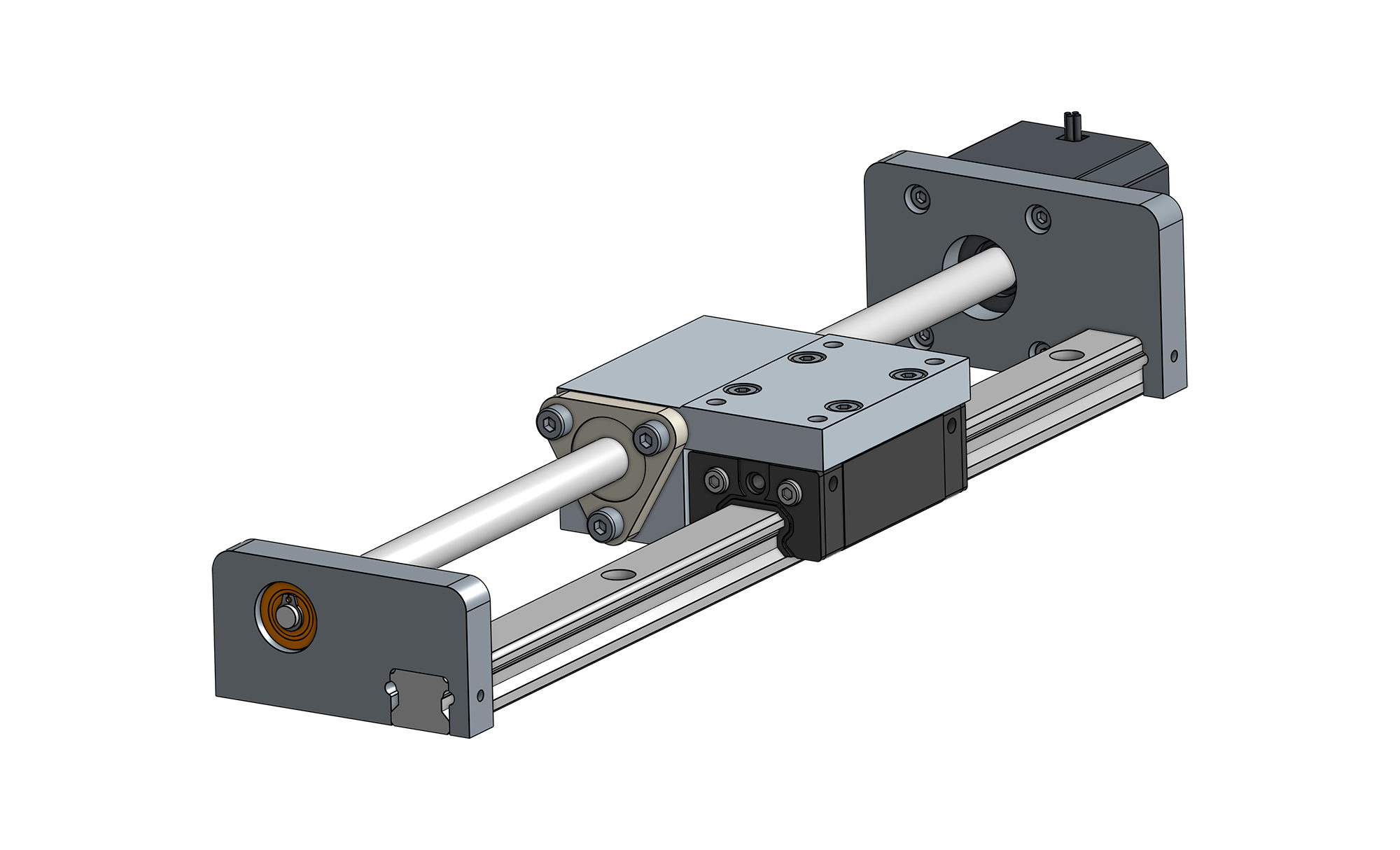

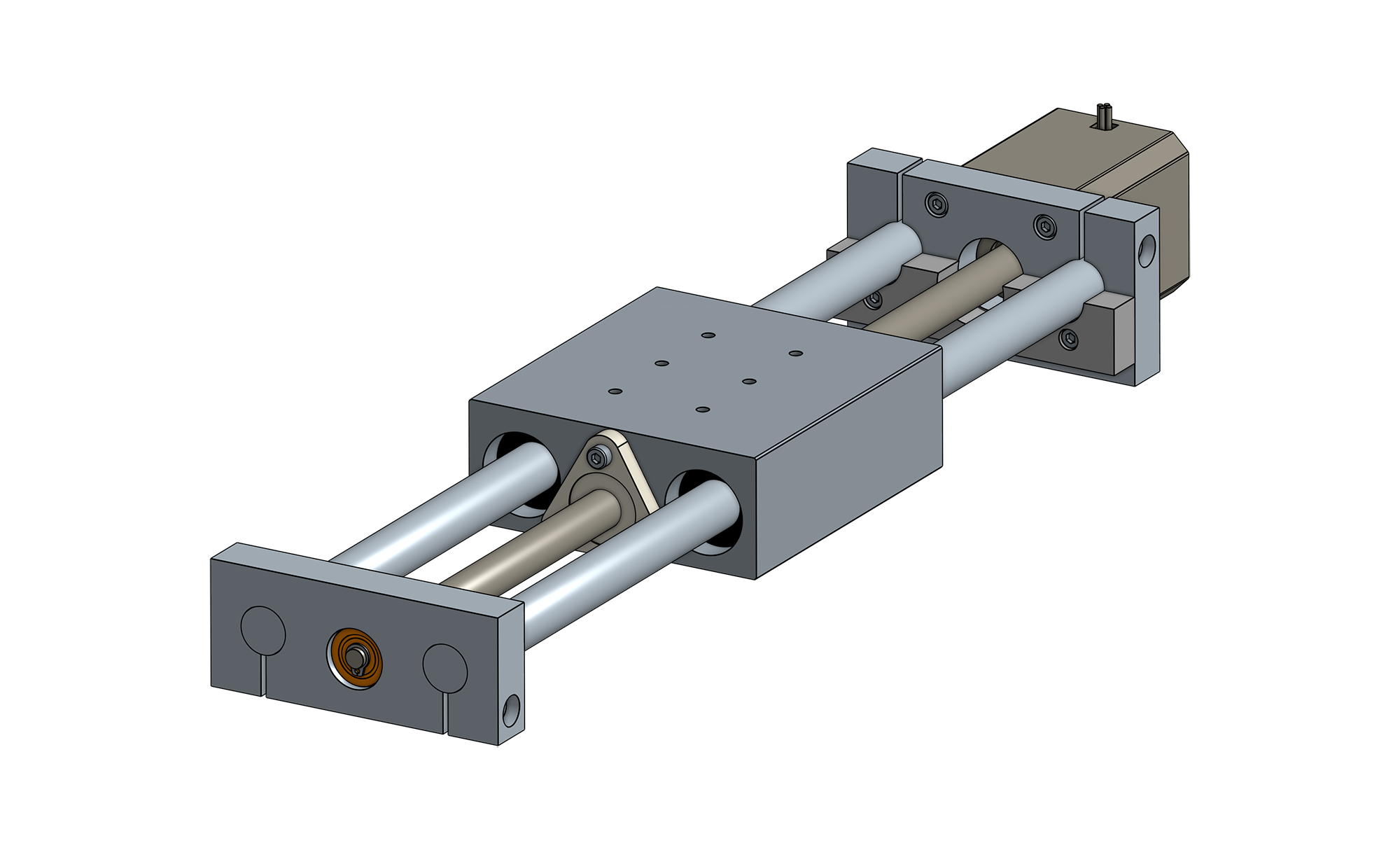

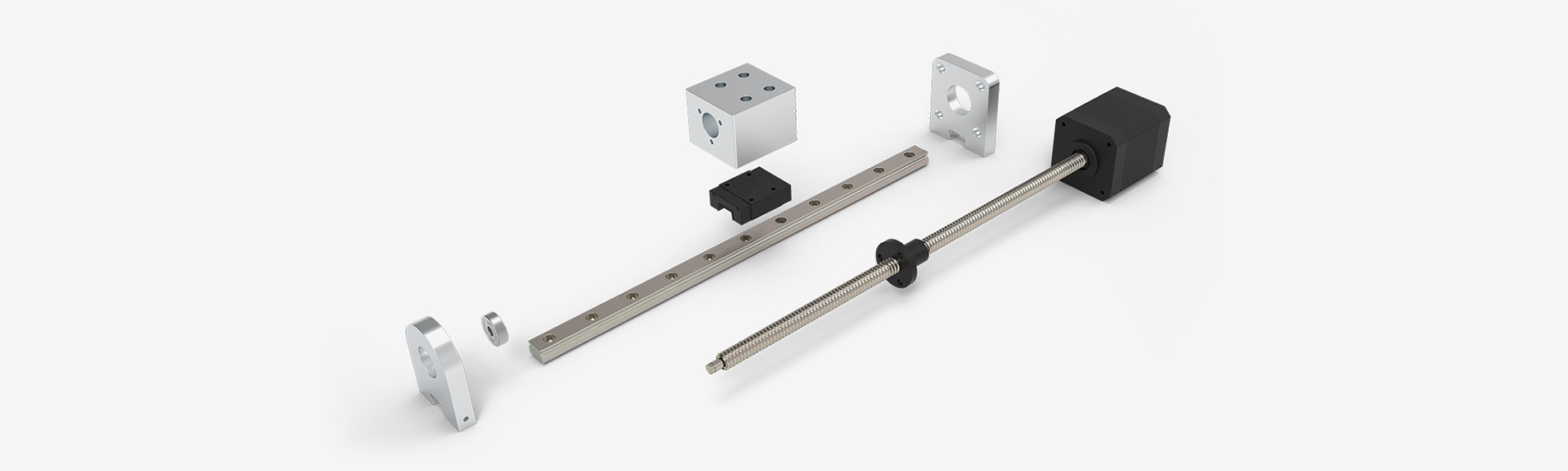

Compact Linear Systems

Take the guesswork out of specifying multiple components for your linear motion designs. Thomson compact linear systems address the need for thrust and bearing support in a single, small-scale unit for space-conscious applications. Whether you opt for one of our three standard architectures (see below) or work with our engineers on a “from scratch” solution, your application requirements will determine the selection and sizing of your system components.